Special Assessment Services For Steam Methane Reformers

HSI Special Assessment Services for Steam Methane Reformers (SMRs) provide invaluable support to process plant owners and operators. Our team of experienced engineers and technicians can perform specialized inspections, assessments, investigation, and repair recommendations for SMR units. From routine maintenance to critical repairs, HSI provides a comprehensive range of services to ensure the safe operation of SMRs across industries including oil & gas, refinery, petrochemical, chemical, and power generation.

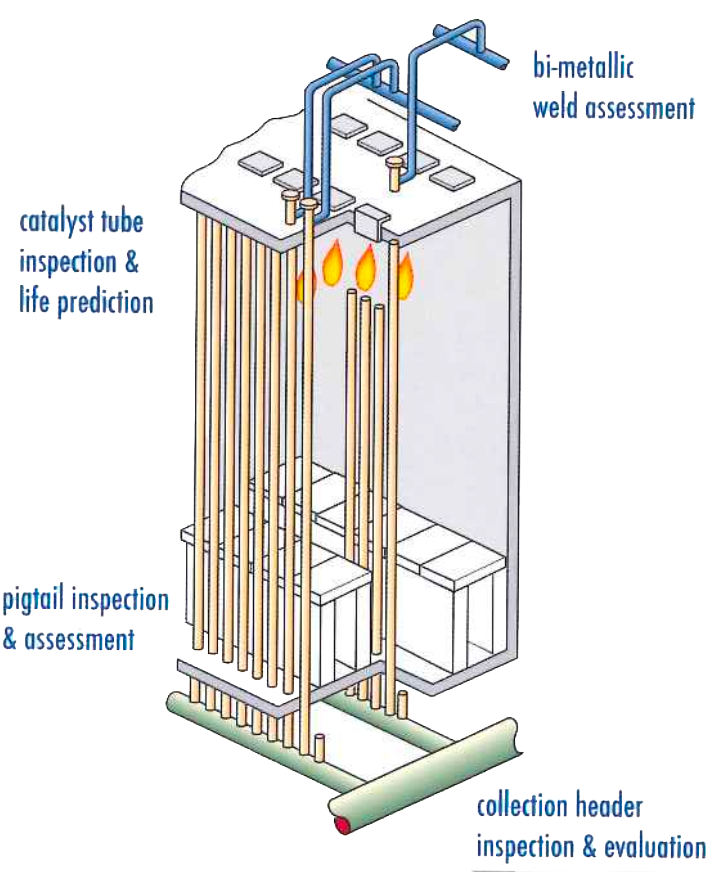

Our experts can inspect the various components that make up your SMR unit – from catalyst beds and tubes to internals, headers, and vessels – to identify any signs of corrosion or wear. We also have the capability to properly diagnose the cause of any damage or corrosion before recommending a course of action.

The Problem

Steam Reformer Furnaces are at the core of many plants used in the production of Ammonia, Methanol, Syngas, Acetic Acid, and refined hydrocarbons.

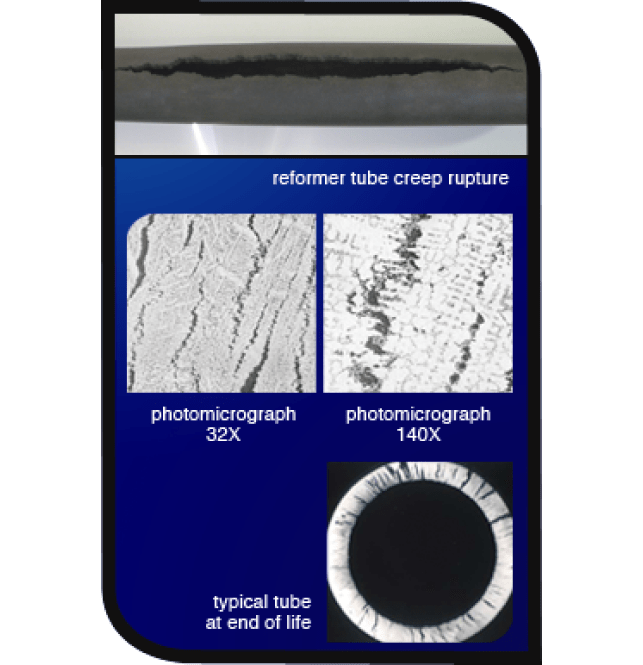

This critical equipment operates under extreme temperatures and pressures, requiring the use of high alloy materials. These materials are subject to long-term degradation due to stresses caused by fatigue, thermal, creep, and residual issues.

Reformer Tubes, Pigtails, and Collection Headers utilize materials which reside in the creep regime. These components operate at the upper limits of the materials structural properties with which they are manufactured. Plant upsets or extreme operating conditions can adversely effect the continued serviceability of the components.

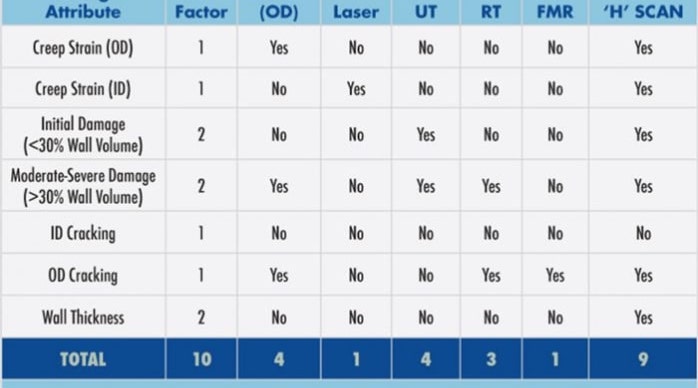

A design life of 100,000 operating hours has been the normal time-based criteria for considering retirement of tubes. Operators of these furnaces require specific assessments which will ensure continued safe operation and tube reliability to optimize plant performance. The damages created within the furnace require assessment techniques and software that will target specific damage mechanisms that result from operation of this equipment.

The Solutions

HSI has developed a complete program of inspection services which will allow plant operators to manage the long-term asset life of plant equipment.

Comprehensive Services Include:

- Reformer Tube Inspection and Condition Assessment

- Remaining Life Assessment

- Header Inspection and Assessments

- Pigtail Inspection and Life Evaluation

- Bi-Metallic Weld Evaluation and Life Prediction

APPLICABILITY OF NDE TECHNIQUES TO DEFINE DAMAGE